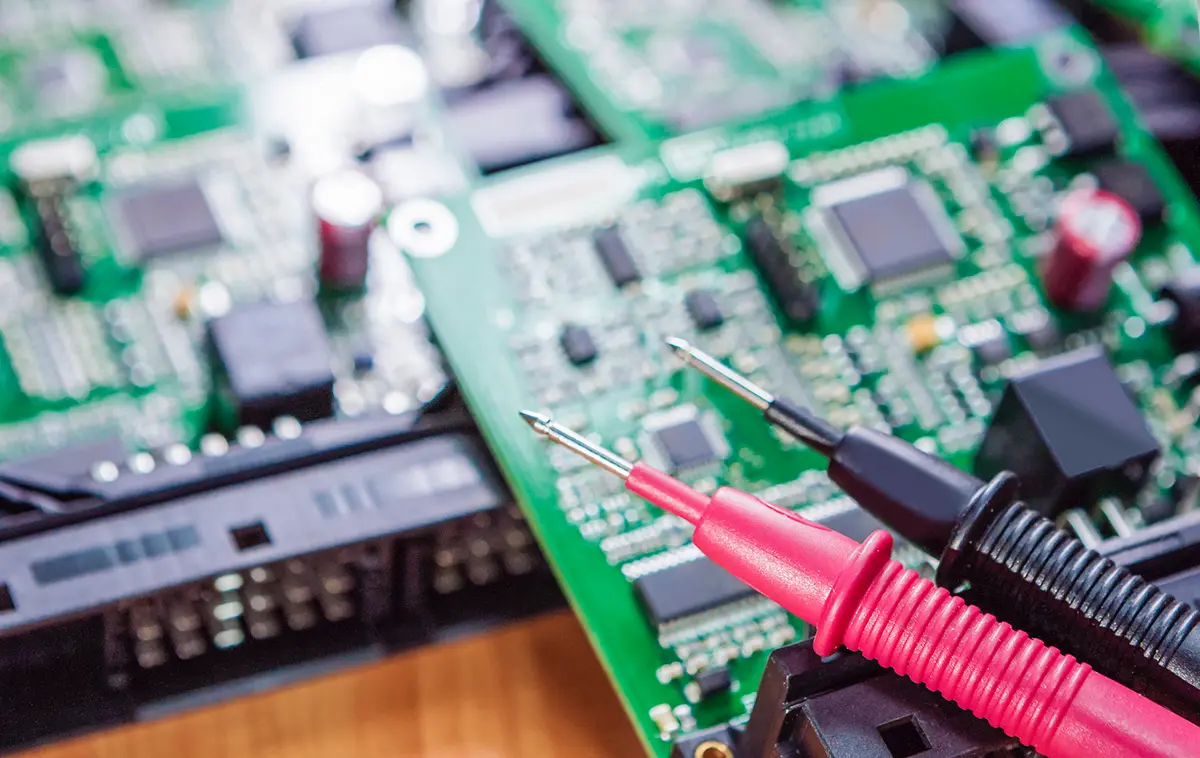

QUALITY ASSURANCE

When you choose TOPTE LINK as your circuit board supplier, you get a company with a decade-long track record of providing high-quality PCB solutions to customer. We make quality the top priority in every phase of our operation, including PCB development, manufacturing and assembly.

We’ve implemented strict proactive steps to verify the quality of our processes and products. Our experienced engineering team checks every PCB design prior to the start of the production/assembly phase to ensure there are no inherent flaws and that the design meets the customer’s exact specifications. We also have a full quality control department on staff to perform comprehensive inspections and testing before shipping the finished product to your facility, including Electrical Test, Automated Optical Inspection (AOI), Automated X-ray Inspection (AXI), etc.